Fibre Optic Guide

Construction

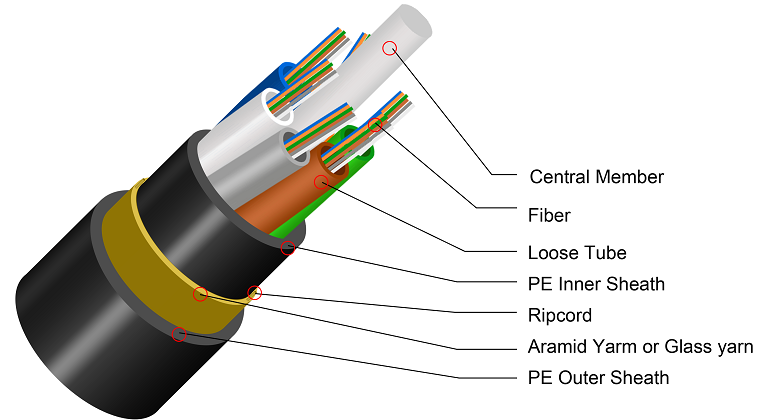

A glass fibre cable consists mainly of three parts: The glass fibre core, carrying the light signal, the glass jacket which reflects the light and a plastic cladding which protects the glass fibre cable from external influences and makes it flexible.

The Fibre Core

There are various thicknesses of the glass fiber core which are described with their cross section: The single mode fiber cable with a cross section of 9µm and multi-mode fiber cables with cross sections of 50 µm and 62.5 µm.

Single mode fiber cables are more costly than multi-mode fiber cables because of difficulties in the manufacture of an extremely thin cable with a cross section of 9µm, but they have a greater range.

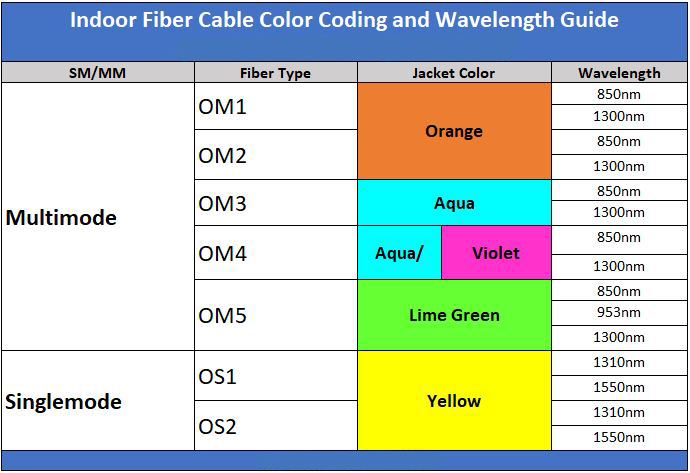

Additional designations are used to describe them in terms of their quality: OS1 and OS2 for single mode fibre cables, where OS2 is the best quality and OM1, OM2, OM3, OM4 & now OM5 for multimode cables – Where OM3 and OM4 are most used, OM5 is the best quality.

While Singlemode is traditionally Yellow in cable colour, OM1 in Grey or Orange, OM2 uses only Orange and OM3 uses Aqua Blue. Our standard OM4 also comes in Aqua Blue, however, many operations use Violet for OM4 as well. So, we can offer those as an alternative. OM5 tends to come in a Lime Green – Although, any colour can be requested for any fibre type if need be.

The Difference Between Singlemode and Multimode

The light is reflected in a zigzag pattern in the core of thicker multimode fibre cables. This results in higher attenuation, the range of the signal reduces, in other words. The light does not refract so frequently in single mode fibre cables and guarantees an enormous range.

There are several forms of cladding for glass fibre cables.

The solid strand type surrounds the fibre directly. This has a disadvantageous effect when there is high strain and with temperature differences.

Unlike the solid strand type, the hollow strand type does not surround the fibre directly. There is a hollow space between the cladding and the fibre which reduces the disadvantageous effects of strain load and temperature differences.

The combined strand type represents an intermediate form of the solid core type and the hollow core type. The hollow space of the cladding is filled here with a gel or similar.

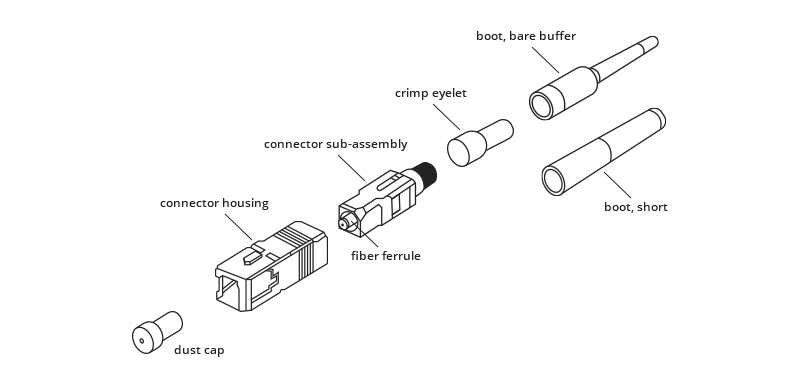

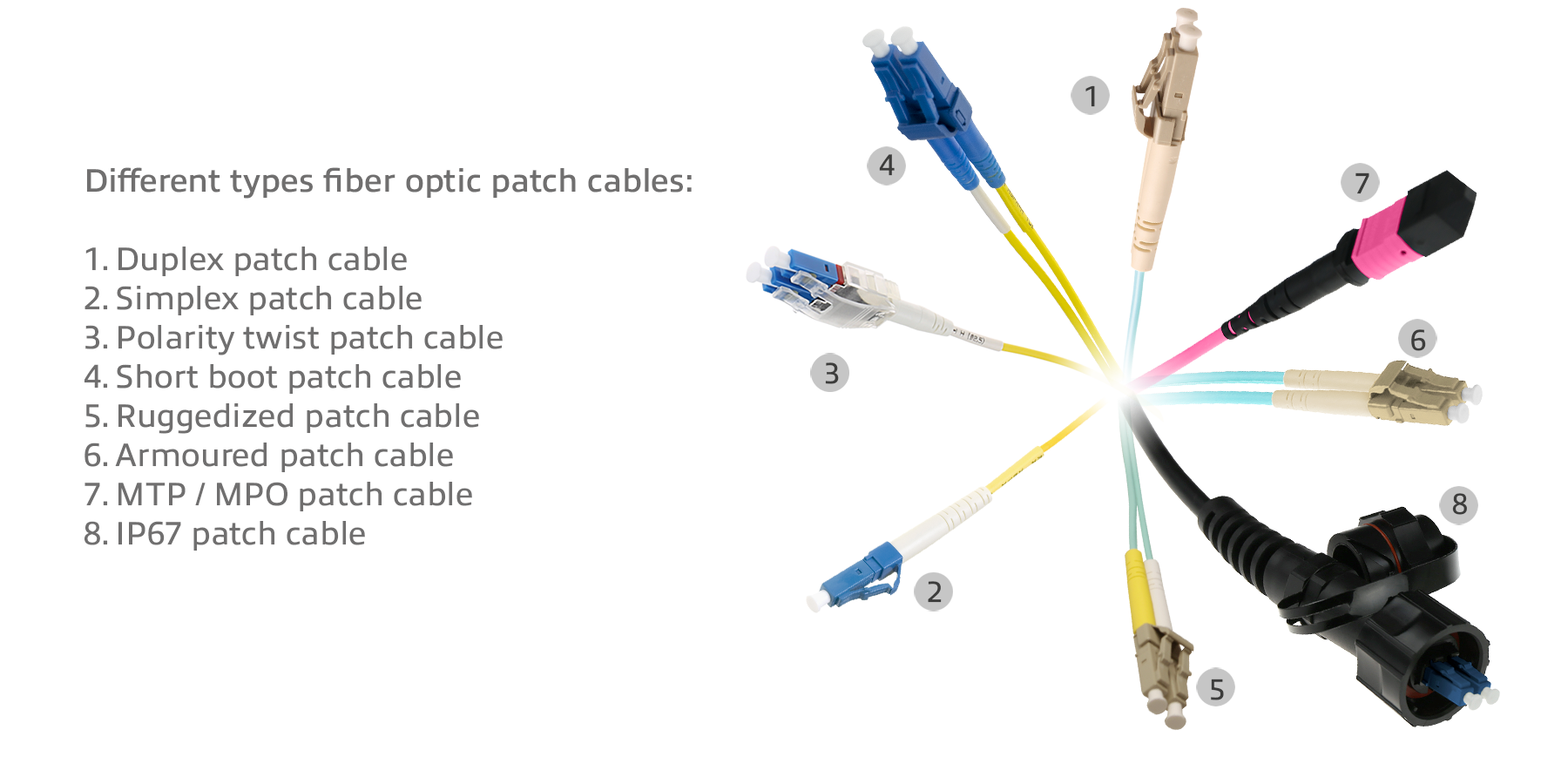

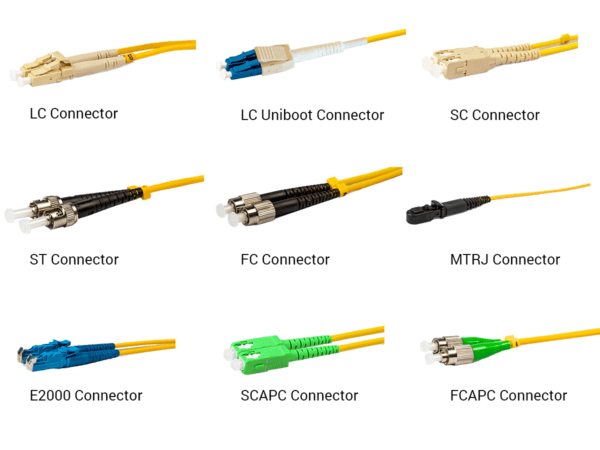

Types of Fibre Plug

LWL plugs

The widest distributed LWL plugs are ST-, SC- and LC plugs. The LC plugs gains an ever increasing share of the market for glass fibre plugs because of the compact size and their use with mini GBIC modules in switches or media converters.

Pigtails

Pigtails are cables equipped with an LWL plug on one side and a plain glass fibre cable on the other side. They are used at the end points of laid cables and are spliced with each other.

Splicing

Splicing is understood to be the connection of two glass fibre cables. These are adjusted at their end points and permanently fused together.