Structured Cabling Guide

Cabling Standards

The standard series of EN 50173 is divided into five areas for various applications and covers application-neutral communication cablings for information technology.

• EN 50173-1 General requirements

• EN 50173-2 Office buildings

• EN 50173-3 Industrially used buildings

• EN 50173-4 Private residential units

• EN 50173-5 Computing centres

There is also a difference in the individual components such as cables and connection technology and also in the installation of these components.

The individual components are classified into the following

categories:

• Category 5 up to 100 MHz

• Category 6 up to 250 MHz

• Category 6A up to 500 MHz

• Category 7 up to 600 MHz

• Category 7A up to 1000 MHz

A distinction is drawn between installed components according to transmission classes

• Class D up to 100 MHz

• Class E up to 250 MHz

• Class EA up to 500 MHz

• Class F up to 600 MHz

• Class FA up to 1000 MHz

Certification and checking of the limiting values for the measurement technology of the installed transmission routes.

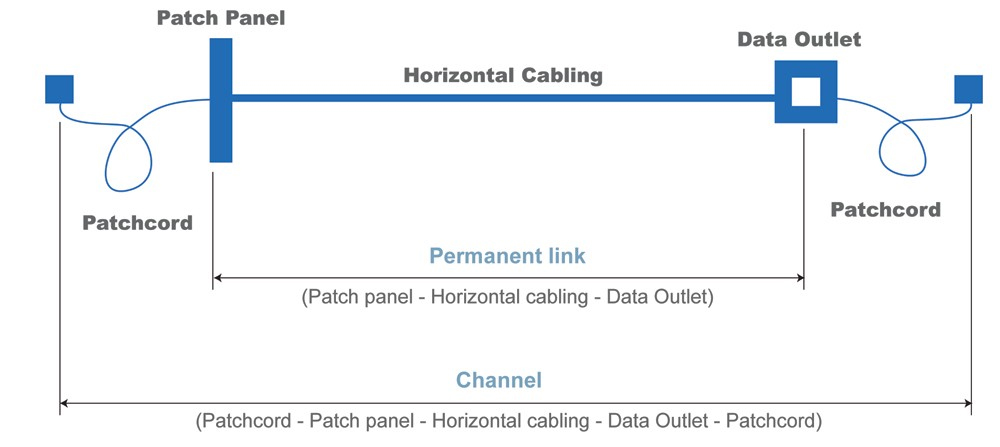

A distinction is drawn between two models for the transmission routes for the cabling.

• Permanent Link – which covers the laid installation cable and also the patch panel permanently connected to the end of the cable and the junction box.

• Channel Link – Where the patch cable also used in the patch panel and the junction box can also be measured together with the components of the Permanent Link.

Structure of the Cabling System in Accordance with EN 50173

Cabling takes place on different levels, not only storeys/floors are cabled but also different floors are cabled with each other and buildings are also cabled over outside surfaces. There different areas are defined for these applications.

• Primary cabling outside site areas, campus backbone

• Secondary cabling building area, building backbone

• Tertiary cabling, cabling in floors, horizontal cabling

Basic standard specifications have been laid down in these cabling areas, as far as the execution of the entire cabling system is concerned.

At least one sub-distribution panel is planned for an office space of 1000m2. Such a sub distribution panel can also serve several floors in smaller buildings. The jacks should be distributed over the entire useable area where there have to be at least 2 connections for each workplace. One of the connections should be at least made with symmetric copper cable, the other one can be connected by using LWL cable.

The following minimum and maximum requirements are imposed on the lengths of cable for cabling in floors. The distance between the user end device and the distribution components, including all the patch cable used must not exceed 100 m.

The length of the fixed cable between the jack and the patch panel is set at a maximum of 90 m here.

The maximum distance in the Permanent Link can also be shorter, since a consolidation point integrated into the cabling runs also has effects on the technical transmission values of the laid cable. Patch cables between jack and end device should not exceed a maximum length of 20 m: the length of patch cable used in the patch field at the floor sub-distribution cable has a maximum length of 5 m. Consolidation points which are used should be placed at least 15 m from the floor sub-distribution panel since plug-in connections used in the immediate vicinity can exert influences on various transmission parameters. The types of cable used in cabling on floors consist of 100 Ohm 4 paired twisted pair cables and 50/125µ multi-mode glass fiber cables.

The maximum cable length of the transmission run should be 2000m for the site and building cabling of the secondary area. The previously mentioned cable types are also preferred here. The often larger distances between buildings also offer an area of use for 07/15µ mono-mode glass fibre cable.

Connection Technology for Structured Cabling

The cable which has been used for laying can be described with the following, different characteristics.

• Copper conductor consisting of solid copper for permanent installation between sub-distribution panels on floors and between distribution panels and jacks.

• Copper conductor as flexible conductor wire for use in the manufacture of patch cables.

• Details of the diameter and/or cross section in mm, mm2 or AWG (American Wire Gauge). The larger the wire diameter, the smaller the attenuation.

This section shows the following examples:

AWG 24/1 = conductor consisting of solid wire with 0.511 mm conductor diameter

AWG 26/7 = conductor consists of 7 wires with 0.48 mm conductor diameter

• Strands are twisted into pairs and provided with a colour code in the conductor insulation. The colour code is done according to EIA/TIA 568 / IEC 708-1 with the wiring:

Pair 1 = wire 1 in white/blue, wire 2 in blue

Pair 2 = wire 1 in white / orange, wire 2 in orange

Pair 3 = wire 1 in white / green, wire 2 in green

Pair 4 = wire 1 in white / brown, wire 2 in brown

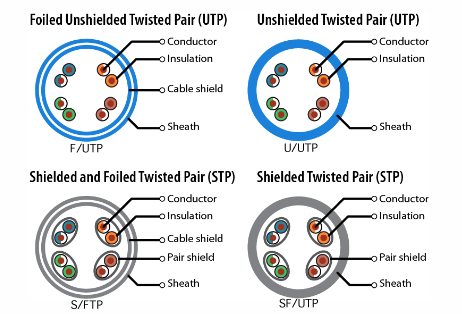

• The screening is used to improve transmission safety. In accordance with the valid standard, it guarantees the limitation of electromagnetic disturbances and also the immunity of the network against disturbances.

UTP completely unscreened, paired unscreened, twisted cable

F/UTP completely foil screened, paired unscreened, twisted cable

SF/UTP cable completely screened with foil and braid, paired unscreened, twisted cable

S/FTP cable completely screened with braid, paired foil screened twisted cable

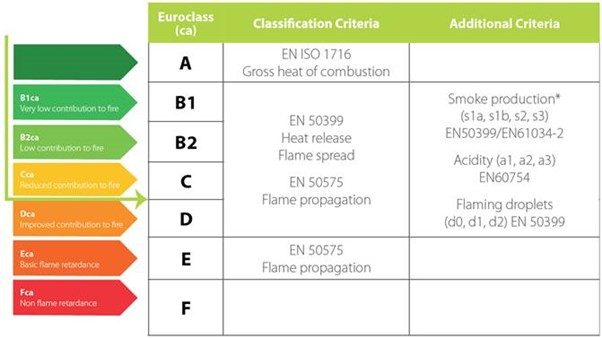

• External cladding consisting of PVC or a halogen-free, fame resistant compound.

Halogen-free = no corrosive, or clearly less toxic gases and very low quantities of smoke

Flame resistant = self extinguishing after removal of the heat source, very limited propagation of fire

FR = flame retardant

LS = low smoke

NC = no corrosive fumes

OH, ZH = no halogen

The requirements for the patch panels and jacks are defined in DIN EN 50173-1. These products are divided into various classes in accordance with the performance class. Optimisation of the products allows panels and jacks to satisfy the requirements when a gigabit Ethernet is being operated. These have been set down in the standards DIN EN 50173-1:2000 with both types, category 3 up to 16MHz and category 5 up to 100 MHz and also in EIN EN 50173:2002 with the types, category5 up to 100MHz, category 6 up to 250MHz and category 7 up to 600MHz.

Category 6 products according to the new standard are only products which have been tested according to “De-Embedded Testing”. This makes sure that the advantages reached by technical and mechanical improvements are used. Each category 6 jack with a RJ45 plug produces a category 6 connection according to standard.

There is the option of using two configurations when cables are laid to patch panels and junction boxes and also when patch cables are being made. A distinction is made here according to colour code in accordance with EIA/TIA 568A or EIA/TIA 568B. The colour code used for the configuration is not important for the respective application, but has to be carried continuously throughout the complete system. Care also has to be taken when processing the patch cable to make sure that the paired twisting remains the same with the exception of the last 13 mm and that the possible pair screening is lead up to the LSA terminal rail.

Different applications run on the pairs / pins in the respective combination.

• Ethernet 1-2, 3-6

• Fast Ethernet 1-2, 3-6

• Gigabit Ethernet 1-2. 3-6, 4-5, 7-8

• 10 Gigabit Ethernet 1-2. 3-6, 4-5, 7-8

• ISDN 4-5, 3-6

• Token Ring 4-5, 3-6

• FDDI 1-2, 7-8

• ATM 1-2, 7-8

Fairline also offer VAT included prices at Computerstar. Find your technology solution online and order with ease!